Precision Defines Your Excellence

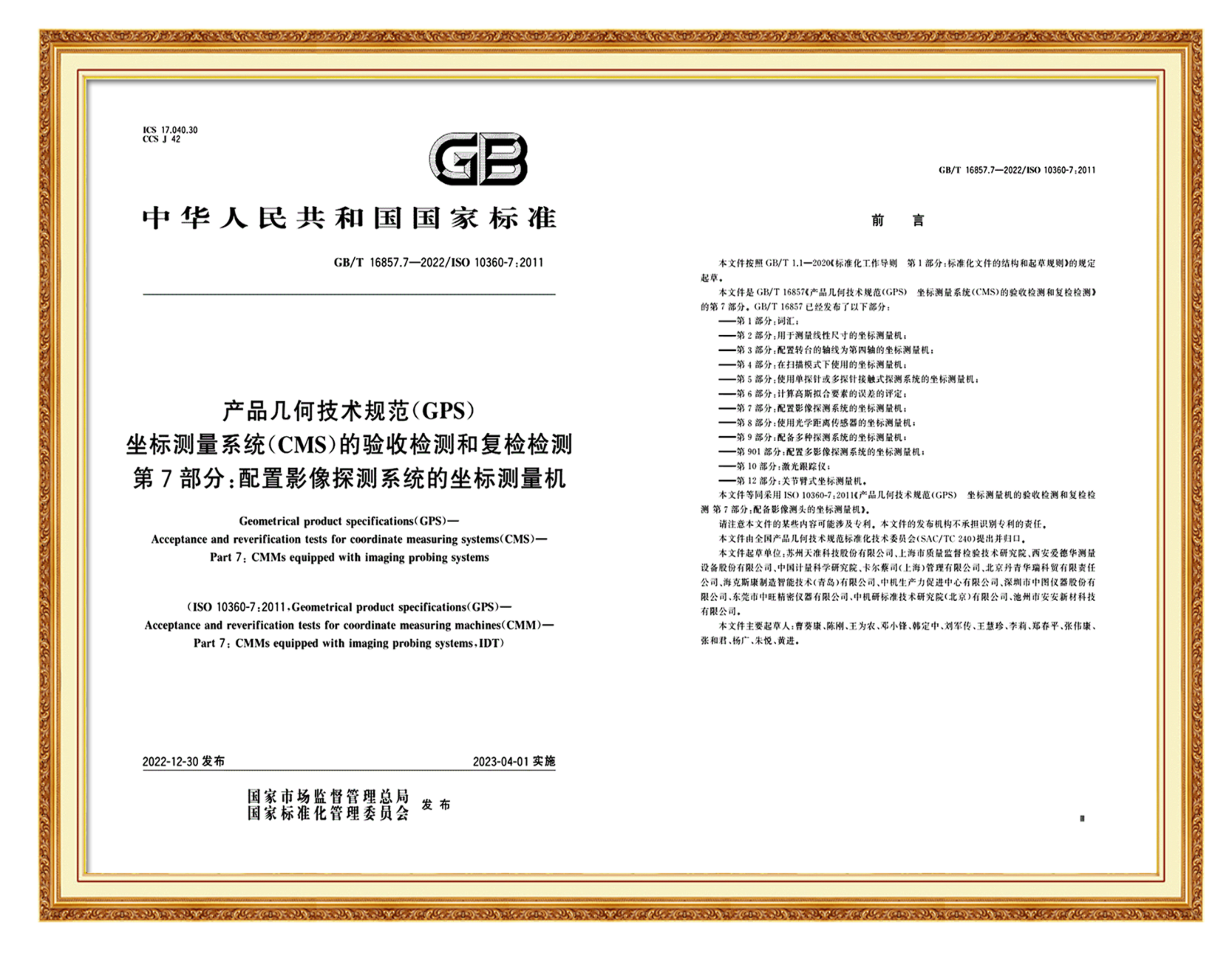

Xi'an AEH Industrial Metrology Co., Ltd. (hereinafter referred to as "AEH Measurement"), founded in 1997, is a national-level high-tech enterprise specializing in precision measurement. In 2023, it was selected as a fifth-batch specialized and sophisticated "Little Giant" enterprise, and has always been committed to breaking through core precision measurement technologies to empower the transformation and upgrading of China's high-end manufacturing. The company relies on three global R&D systems in Xi'an (China), Aschaffenburg (Germany), and Cholet (France), and owns independent subsidiaries including Dongguan Dexin Optics, MORA (Germany), WENZELDESIGNTEC (Germany), and INSPECT3D (France). It has built an advanced technology system centered on embodied intelligence, blade measurement, composite measurement, the EMRP intelligent quality management platform, intelligent inspection units, and full measurement chain solutions, achieving full-chain technological integration from core algorithms to precision hardware. With over 120 independent intellectual property rights and experience participating in multiple national standards, AEH provides integrated "hardware + software + service" solutions for strategic fields such as aerospace, automotive manufacturing, semiconductors, and research institutes. AEH adheres to a "people-oriented" development philosophy, treating talent as the cornerstone of growth and building an engineering team with craftsmanship and a global vision. Relying on a global service network that covers all 34 provincial-level administrative regions in China and extends to more than 30 countries including the United States, Germany, France, the United Kingdom, South Korea, Singapore, and India, AEH provides full lifecycle support for products and technologies, and advances China's precision measurement capabilities toward a globally leading position through a collaborative, win-win industrial ecosystem.

Corporate Culture

Vision

To become a global leader in precision measurement and build a world-class platform in the measurement industry

Mission

Using measurement technology as a leverage point to support the great cause of a manufacturing powerhouse

Values

Customer-oriented, creating value for customers; People-oriented, realizing employee value.

Certificates

View More

Comprehensive Strength

ISO9001 Quality System Certification

Subsidiaries

Service Outlets

Provinces Covered

Countries Worldwide

Digital Inspection Tech Centers

Wholly-Owned Subsidiaries

摩拉测量技术有限公司(MORA)

高端三坐标测量/拥有 MORA,掌控质量

MORA 创立于1909年,总部位于德国阿沙芬堡,是全球工业测量领域历史最悠久的品牌之一。1973年,MORA 推出全球首台气浮导轨大型三坐标测量机;1992年,首创悬臂铣削测量一体机,将白车身研发验证周期压缩至48小时,至今仍是行业标杆。其 INCA3D 五轴铣削软件在复杂曲面加工检测领域享誉全球,客户涵盖博世、西门子、奔驰、宝马、中国计量科学研究院、中航工业、中车、中船等国内外头部机构与核心企业。2009年,爱德华测量收购 MORA,成为爱德华测量全球化战略的重要组成部分。作为爱德华“精密测量矩阵”中高端大尺寸与复杂曲面解决方案的核心承载者,MORA 将继续以“拥有 MORA,掌控质量”的百年承诺,为中国高端制造提供世界级测量技术与定制化解决方案。

Wenzel DesignTec

高端铣削与造型研发/更快抵达完美造型

Wenzel 铣削业务起源于1992年,是全球汽车设计造型室领域悬臂油泥铣削机的开创者之一。2016年,温泽集团将铣削业务剥离成立独立公司 Wenzel DesignTec GmbH,总部位于德国赫斯巴赫,在亨格尔斯贝格设有生产基地。三十余年来,温泽铣削设备及 DesCAD、Design Master 软件被全球主流汽车品牌设计中心广泛采用,多次获得红点、iF 等国际设计大奖。2025年,爱德华测量收购 Wenzel DesignTec。作为旗下独立运营的德国高端铣削品牌,Wenzel 将继续以“更快抵达完美造型”为使命,为中国及亚太汽车设计、轨道交通、航空航天等领域的造型研发提供世界级的油泥铣削、代木加工及数字化造型解决方案。

法国 INSPECT 3D 软件公司

工业测量软件/软硬协同测量平台

INSPECT 3D 总部位于法国,专注于工业测量与三维计量软件的研发。INSPECT 3D 加入爱德华测量后,成为集团旗下独立运营的法国软件研发中心。公司核心产品 INCA 3D 测量软件是悬臂测量机、铣削测量一体机的专用软件平台,在汽车白车身研发与产线检测领域拥有深厚积累。其技术能力涵盖点云处理、叶片测量、影像测量、齿轮测量等专业应用模块,可为复杂曲面检测、大尺寸工件测量提供高效、精准的软件解决方案。作为爱德华测量“精密测量矩阵”中软件技术路线的重要承载者,INSPECT 3D 与 MORA 硬件产品形成软硬协同的整体解决方案,持续为全球汽车制造、航空航天等领域用户提供创新测量体验与技术支持。

东莞市德鑫光学仪器有限公司

光学影像测量/全链条自主可控

德鑫是爱德华测量旗下全资子公司,2009年成立于东莞,专注于光学影像测量技术的研发与制造。作为爱德华在华南地区的重要布局,德鑫承担影像测量仪、光学坐标测量机及复合式光学测量设备的产业化任务。公司汇聚光学测量领域资深专家团队,在2D/2.5D/3D影像测量、多传感器融合及光学软件平台方面形成完整技术能力,产品广泛应用于3C电子、精密五金、半导体封装等领域。依托爱德华自主研发的测量软件与控制系统,德鑫实现光学测量设备从核心算法到整机集成的全链条自主可控。作为集团“精密测量矩阵”中光学技术路线的主力承载者,德鑫致力于为华南及全球客户提供高精度、高性价比的光学测量解决方案。

BLOG

News & Events

Leave your email

Get our latest updates

Global Presence

AEH business is distributed across 34 technical R&D and after-sales service points worldwide